Our Expertise

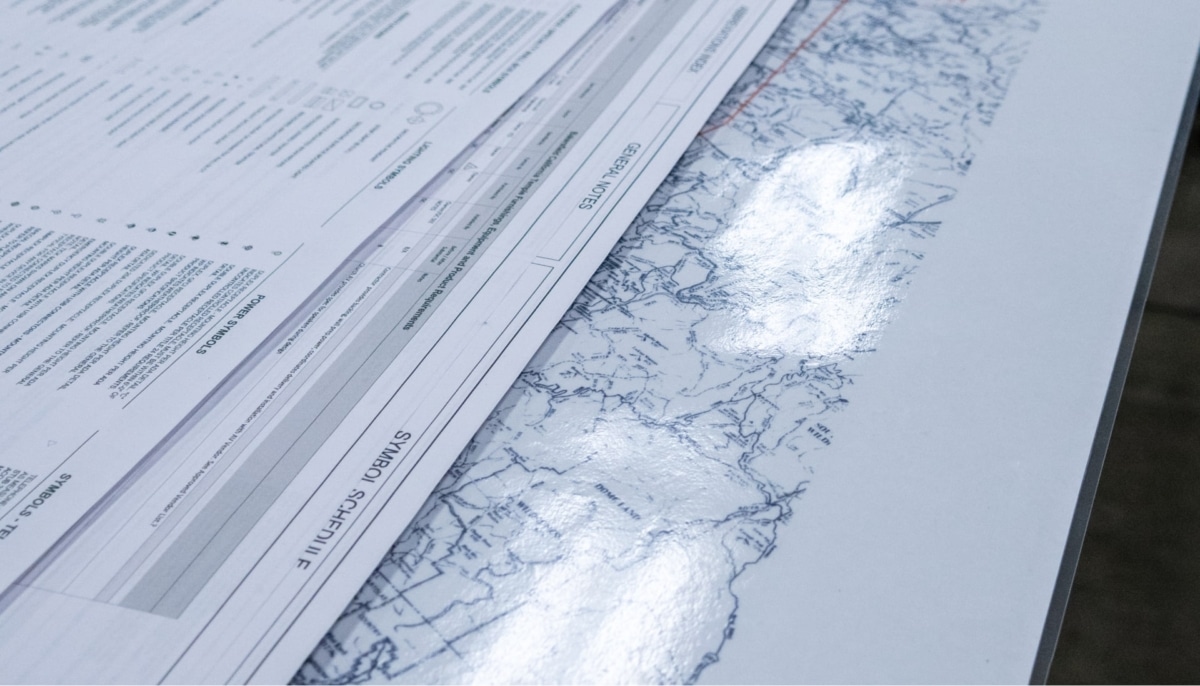

Preconstruction

Our team of engineers, virtual construction designers, CAD operators, and craftsman work closely together to value engineer each project utilizing BIM software and comprehensive planning processes to reduce job costs, improve project scheduling, and streamline project management.

Prefabrication Advantage

Our state-of-the-art, in-house prefab capabilities allow us to assemble components in a controlled environment, reducing job site waste and congestion. Our logistics team meticulously plans shipping, ensuring clean and damage-free deliveries.

Innovation & Process Optimization

Our modular shop is fully adaptable and allows for quick reconfiguration based on project needs. We invest as much time in refining workflows as in fabrication, preventing issues before they arise.

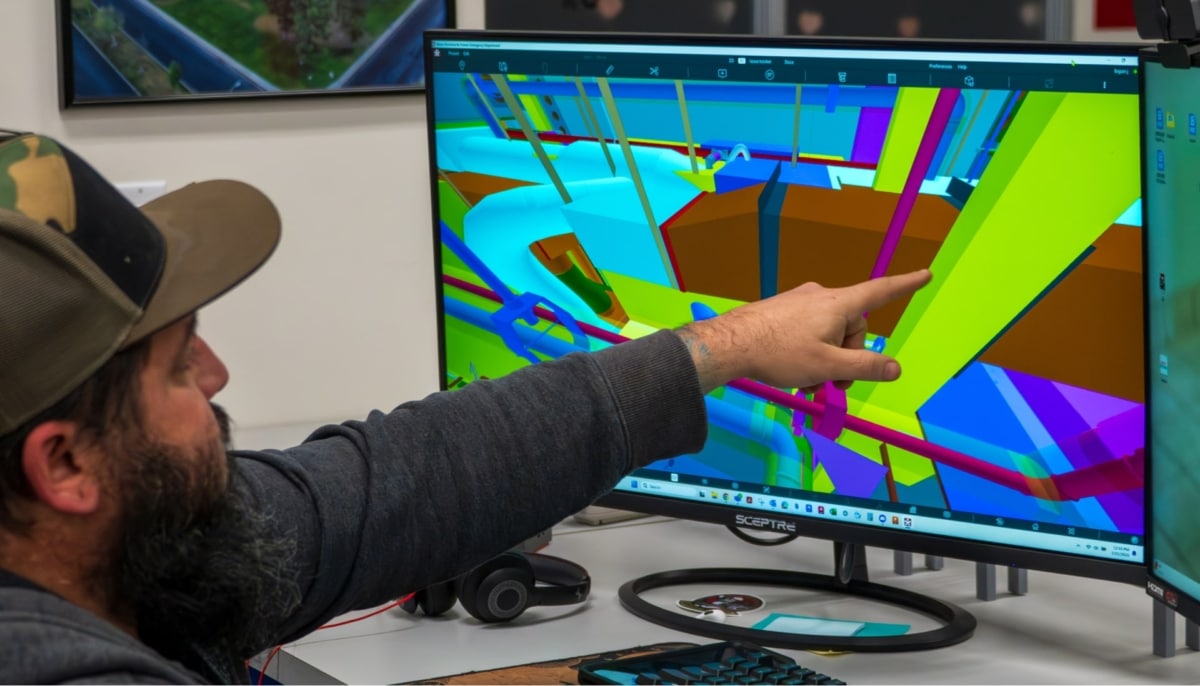

Building Information Modeling (BIM) Integration

Highly accurate BIM models guide fabrication and installation within a 1/16” tolerance. BIM models provide a lasting reference for future maintenance, with clear documentation of underground and in-wall utilities.

Our Process

Detailed measurements that capture the dimensions of your facility down to the centimeter are taken in a matter of minutes by a single operator.

The 3D laser scanning tool is able to capture accurate measurements even in tight spaces or difficult conditions.

The tool converts the measurements into precise electronic as-built drawings, drastically reducing time and the possibility for human error.

The operator who takes the measurements works closely with the Virtual Construction Design Team to craft a seamless design.

3D design allows the VC Designers to anticipate issues and create solutions prior to crews arriving on site.

Facilitates installation coordination between the VC Design Team and facility management prior to construction, minimizing the impacts to your facility.

The comprehensive design is given to the prefabrication team at an off-site location for construction of a controlled, high quality product.

Project is fabricated by specialized craftsmen in A-C Electric Company’s fabrication facility, stocked with top-of-the-line materials and tools.

Layout of installation is performed by a Total Station robotic layout tool prior to installation crews arriving.

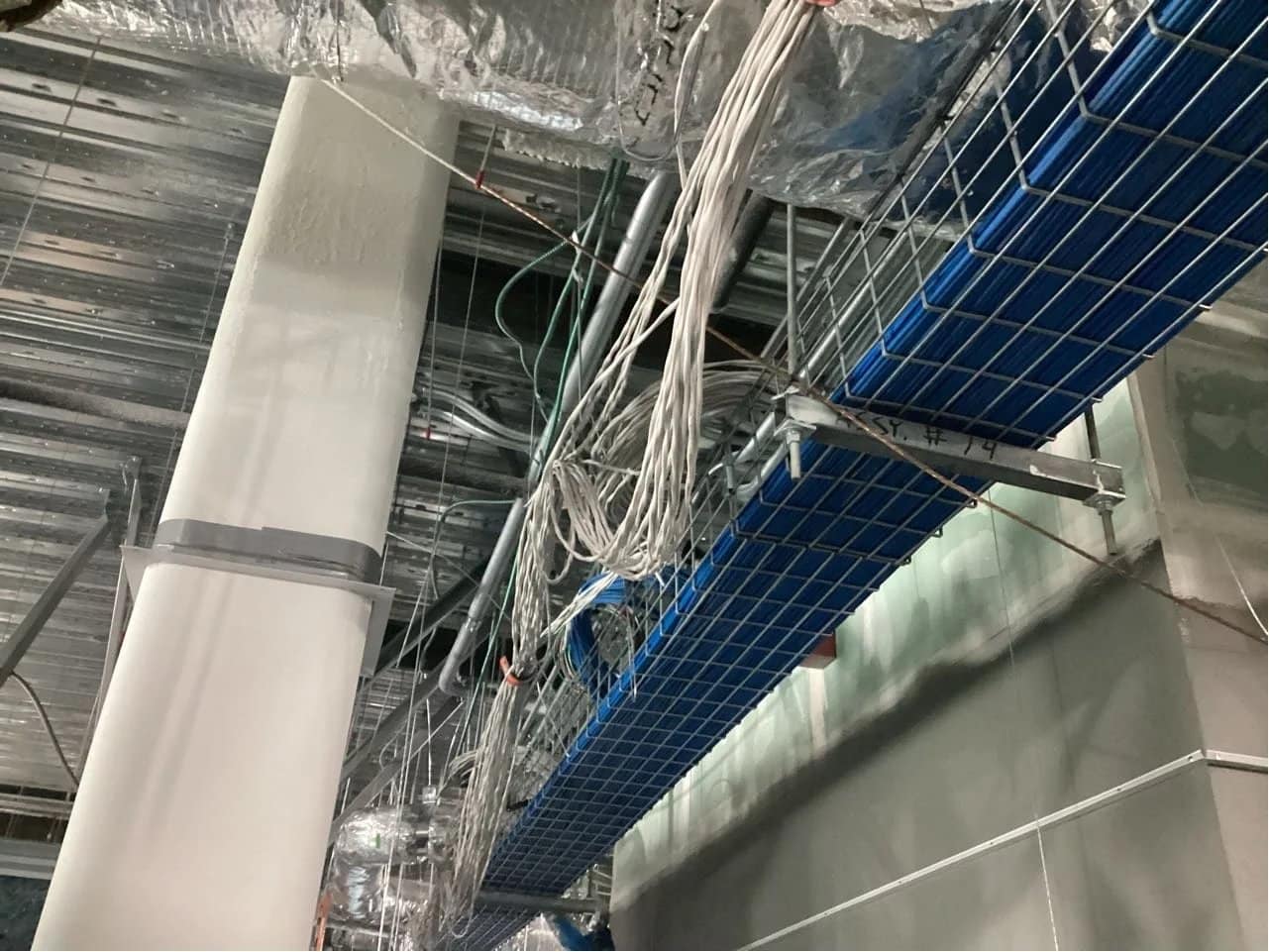

The prefabricated build is sent to the installation team with detailed design drawings and a clear path for installation.

On-site installation, rather than on-site construction, reduces the amount of time in your facility and volume of personnel needed to accomplish the project.

A clean installation minimizes the likelihood of contamination by foreign construction particles.